Msikaba Bridge, Eastern Cape, South Africa

Msikaba Bridge, Eastern Cape, South Africa

High above the Msikaba River in South Africa’s Eastern Cape, a new landmark on the rural landscape is taking shape: the 580m wide Msikaba Bridge.

The cable-stayed structure will span the spectacular 198m deep Msikaba Gorge, making it one of the highest bridges in Africa, exceeded only by the South Africa's Bloukrans Bridge at 216m and once completed, Mtentu at 223m.

The Msikaba Bridge forms part of the N2 new toll road between Port Edward and Umtata in the Eastern Cape being developed by South African National Roads Agency Limited (SANRAL). It is being constructed by the CME joint venture, a local partnership between Concor and MECSA. Work got under way in 2019.

The project has now reached the most difficult phase: construction of the pylon superstructure and the deck segment lifting activities.

The bridge is being built from both the north and south banks of the gorge and comprises two identical ‘halves’, each spanning 290m, which will meet mid-point over the gorge. Each half is supported by 17 pairs of cables attached to 128m high inverted Y-shaped concrete pylons, one on each side of the gorge.

Currently being slip-formed from the bifurcated legs of the pylons, each of the pylon spires extend 95m from the bifurcation to the top of each pylon.

The two inclined legs meet 21m from the start of the bifurcation which extends a full 11m. At 32m, the first section of the spire – starting with a diameter of 6m – is uninterrupted for 55.7m and comprises 14 slipform lifts. Then begins the inclusion of 17 anchor inserts over the next 35m of the spire, which reaches a height of 124m and will have converged to a 4m diameter. These anchor inserts accommodate the 17 cables that run from the anchor blocks located behind each pylon to the spire, and then down to the 580m-long bridge deck.

To accomplish the lifts, a jacking system is being used for the formwork shutters, with eight jacks around the circumference of the spire. Each lift is 3.6m conducted at intervals of about two weeks per lift.

The work is accessed using a specialised stair system, with one set of access stairs from ground level to the top of the bifurcation and a second stairwell to follow the shutter system up the spire. The formwork system comprises three decks that trail below each other; the interlinked decks lift together as the shutters are jacked up.

The depth of the gorge means that no work on the bridge deck itself can be done from ground level. Everything has to be done suspended from these two pylons – one on the south side of the gorge and one on the north side of the river.

Like the leg of the bridge pylon, the reinforced concrete spire – with walls a metre thick – is hollow to reduce weight and is formed in a tubular design that significantly improves its strength-to-weight ratio. The reinforcing bar used in the spire includes 12-16 mm bar as lacing, with primary bars of 30 and 40mm bar employed in high densities to carry the significant loads.

Once the stays and bridge are in place, the load on each pylon will amount to around 7,000 tonnes. The pylons are well advanced as of early June 2023, with about half of the planned concrete volumes already poured by the top of bifurcation. After the last anchor insert, a 4m parapet will be constructed around the very top of the pylon spire. Access to the inside of the pylon will be restricted to engineering inspections and maintenance.

Each of the two bridge pylons has 17 anchor inserts, with each insert weighing 8-10 tonnes. The inserts are constructed from structural steel and secure the cable stays in place at the top of the pylon. Each cable is made up of between 46 and 58 strand cables – with each stand cable containing seven strands.

The rear cables run back to the two anchor blocks and those running to the front link into the bridge deck itself. The lowest strand cables feed to the deck segments closest to the bridge pylons, while the highest will link into the furthest deck segments mid-span of the bridge deck over the Msikaba River.

Indicative of the precision engineering being employed on this project is the number of activities that must take place at the same time and in a confined area. By the time the fifth anchor insert has been completed, for instance, the launching of the first deck segment will have begun, followed shortly by the second and third segments. While these activities are taking place, the spire and inserts will continue to be erected and cast. The pylons are both expected to be complete in September 2023.

An intense focus on safety has characterised the project, in line with Concor’s Zero Harm policy and protocols. Despite the high-risk site which has included excavations of up to 17m for the pylon anchors, the site team in early June achieved 3.5 million Lost Time Injury Free hours. Preparation for working at heights is a particular priority, with specialised training mandatory for these activities. Significant wind loads can occur at the site, gusting up to 80 km/h.

There are approximately 300 people working on the north and south banks of the bridge, with an additional 280 people currently engaged in various community and local upliftment projects in the vicinity and a further 80 people in the engineering team and laboratory support staff.

The CME JV has recruited about 70% of its workforce locally, all of whom have been given intensive on-site training. It has also identified and supported around 40 local SMMEs, who have been appointed as sub-contractors and suppliers.

The project is expected to be completed in the last quarter of 2024. The Msikaba Bridge will be the largest cable-stayed bridge in South Africa.

Now let's have a look at some photos supplied by Concor.

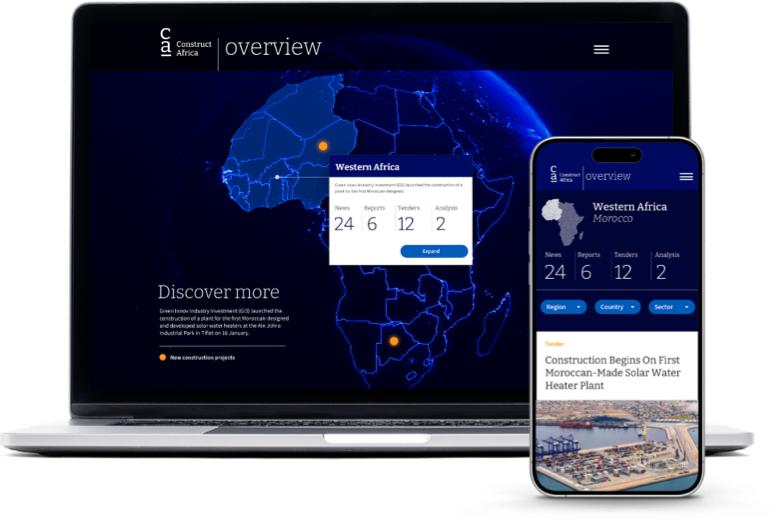

Discover

myConstructAfrica

Your one-stop-shop for information and actionable intelligence on the construction and infrastructure pipeline in African countries

- News, analysis and commentary to keep up-to-date with the construction landscape in Africa.

- Industry Reports providing strategic competitive intelligence on construction markets in African countries for analysts and decision-makers.

- Pipeline Platform tracking construction and infrastructure project opportunities across Africa from conception to completion.

- Access to contact details of developers, contractors, and consultants on construction projects in Africa.

- News and analysis on construction in Africa.

- Industry Reports on construction markets in African countries.

- Pipeline platform tracking construction and infrastructure projects in Africa.

- Access to contact details on construction projects in Africa.